scCO2 and liquid CO2 have several applications in textile production supply chain:

(a) Dyeing,

(b) Pre-treatments (scouring)

(c) Post-treatments (infusion of functional additives)

scCO2 is well suited as an environmentally friendly solvent/medium for dyeing textiles in the form of yarn, thread or fabric. We have developed an efficient process for polyester dyeing. scCO2 is ideally suited for dyeing polyester because many of the disperse dyes used for dyeing polyester are soluble in scCO2. In addition, the disperse dyes are not soluble in water; hence they are mixed with large amounts of surfactants or modifiers so the dyes can be dispersed in water. With scCO2 as solvent, no surfactants or modifiers are needed hence press-cake or crude dyes can be dissolved directly in the scCO2, thereby reducing dye costs and eliminating a large amount of additives that would conventionally end up in the waste water stream.

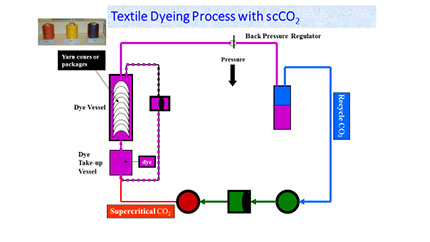

The eCO2Dye general process for dyeing in scCO2 is a batch process and is shown in the diagram.

Dyeing in scCO2 is done in a temperature range of 80 to 120oC; the pressure in dyeing vessel is in the range of 200 to 250 bar. The specific dyeing conditions are selected based on the desired color for the textile. The overall process time is 60 to 90 minutes, depending on the color and the size of the dyeing system.

Textile Dyeing

eCO2Dye has demonstrated dyeing of other man-made textiles including acrylics, nylon and polylactic acid in scCO2. A limited number of dyes have been selected for dyeing these materials.

While our focus has been on polyester, eCO2Dye has demonstrated success on other man-made textiles.

Dye Man-made Materials

Pre-Treatments

scCO2 for Scouring : Cleaning of yarns and fabrics done prior to dyeing or printing

Production of yarns and converting these into fabrics by weaving or knitting processes requires use of various oils, waxes, lubricants and other additives to facilitate in the fabrication steps. The processing aids are removed from the textile to obtain high quality dyeing or printing on the textile. Processing aids are used for all textile materials – natural and man-made, though they may differ chemically depending on the material.

Conventionally the above processing aids are removed by washing with water, surfactants, caustic soda, emulsifiers

- Large water use – as much as 40 l/kg textile

- Extracted materials end up in waste water

- Typically >90% of extraneous materials removed

In our work we have shown both in the lab and the pilot scale that scouring is technically viable and amenable to commercialization for natural and man-made textile materials.

Post-treatments

Textiles are frequently treated with additives which allow properties of the fabric, for example, to be modified to improve customer liking for the textile or for improving the performance of the textile in machine handling.

eCO2Dye has worked with numerous additives such as silicone oils that can be infused into the textile to improve the “feel or softness” of the textile fabric. We also offer treatments for yarns that reduce the friction of the surface of yarns to enhance the processing of the yarn in knitting and weaving operations.

Pre / Post Treatments

Natural Textile Materials

Typically the dyes used for dyeing natural textiles (cotton, silk, wool) do not dissolve in scCO2 and hence dyeing these materials in scCO2 is not straightforward. Dyes and processes for this purpose are being developed. eCO2Dye is developing novel technologies which will allow cotton to be dyed in scCO2.