scCO2 and liquid CO2 have several applications in textile production supply chain:

(a) Dyeing,

(b) Pre-treatments (scouring)

(c) Post-treatments (infusion of functional additives)

scCO2 is well suited as an environmentally friendly solvent/medium for dyeing textiles in the form of yarn, thread or fabric. We have developed an efficient process for polyester dyeing. scCO2 is ideally suited for dyeing polyester because many of the disperse dyes used for dyeing polyester are soluble in scCO2. In addition, the disperse dyes are not soluble in water; hence they are mixed with large amounts of surfactants or modifiers so the dyes can be dispersed in water. With scCO2 as solvent, no surfactants or modifiers are needed hence press-cake or crude dyes can be dissolved directly in the scCO2, thereby reducing dye costs and eliminating a large amount of additives that would conventionally end up in the waste water stream.

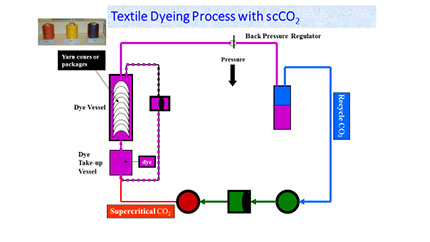

The eCO2Dye general process for dyeing in scCO2 is a batch process and is shown in the diagram.

The key Process Steps are

• Load DRY textiles and dyes into pre-heated dyeing vessel

• Pump CO2 to the desired pressure as a liquid

• Bring vessel to pressure with CO2 at supercritical conditions

• scCO2 is circulated in the system for about 30 minutes to complete the dyeing

• Dyed textile is leveled in the dyeing vessel

• CO2 is depressurized. The CO2 is recycled for re-use. More than 95% of the CO2 is recycled.

• Dyed textile is removed DRY from the vessel.

• The system is now ready for the next cycle.

Dyeing in scCO2 is done in a temperature range of 80 to 120oC; the pressure in dyeing vessel is in the range of 200 to 250 bar. The specific dyeing conditions are selected based on the desired color for the textile. The overall process time is 60 to 90 minutes, depending on the color and the size of the dyeing system.

Textile Dyeing